5R Strategy - Repair

Rethink, Recover, Repair, Reuse, Recycle. These are the 5 key pillars of a strategy to support circular economy in the textile industry, the 5R strategy.

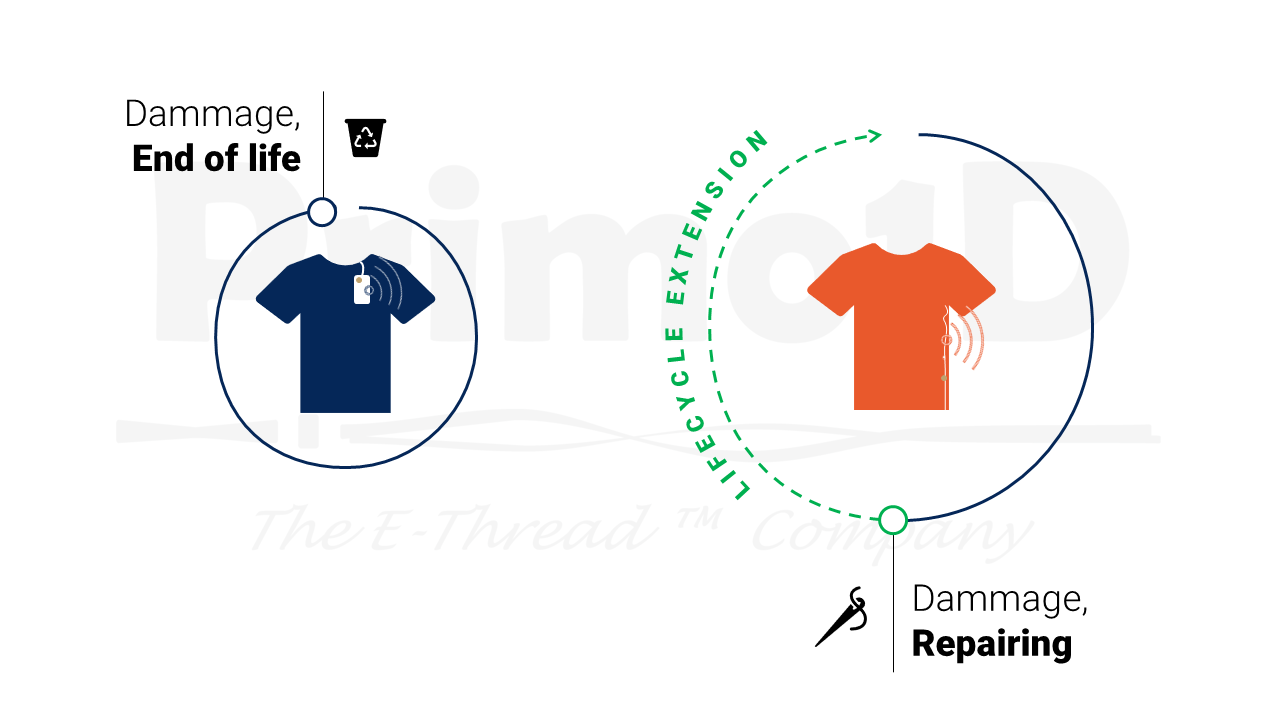

As it enables optimization and extension of assets lifecycle, repairing is a key element for sustainability.

Repairing within the textile sector

Articles repairing is not a new practice within the textile sector. However, it is not systematic in every market.

The workwear market especially democratized repairing and maintenance of textile assets. May it be for people safety reasons or trademark issues, equipment allocated to employees must remain in good shape.

For these reasons, workwear condition is regularly evaluated in order to identify the necessary maintenance. In some countries, the workwear management business model is based on renting. Hence, maintenance and repairing is taken over by renters sometimes working with subcontractors.

RFID supports repairing

RFID brings many benefits to ensure workwear compliance status. It provides essential information such as:

- The equipment production year

- The last maintenance

- Eventual former reparations

- Etc.

All these elements significantly optimize workwear maintenance, may it be its regularity, eventual caution from previous reparations, or end of life assessment.

Yet, traditional RFID tags have their limits in terms of comfort and efficiency related to how they are attached to their assets. In fact, classical RFID tags are prone to get detached by incommoded users or to come loose and fall by accident. All the necessary information for repairing and maintenance, as well as garments background, would be lost.

Thanks to its E-Thread™ technology, Primo1D has rethought the RFID form factor as a non-detachable, seamless, and durable thread. Integrated directly during the manufacturing process or on existing stocks, it does not incommode users and remains in the garment during its entire lifecycle. As a durable tag, it ensures garments information and background remain. Finally, the composition and form factor of the Primo1D tag enables it to undergo the recycling process with the garment.

From compliance status to lifecycle optimization

Repairing became common practice on the workwear market but it has yet to develop on the retail market.

Nonetheless, emerging business models offer to rent some specific clothes, in particular textile equipment requiring a certain investment to purchase.

Thereby, brands must ensure the compliance status of clothes and equipment they rent, which involves maintenance and repairing.

For renters, it is also a way to make better profit by optimizing rented assets’ lifecycle and keeping them compliant.

Repairing is a direct answer to sustainability because it enables articles to keep going on their lifecycle instead of being thrown away when they are damaged.

Just as for workwear, embedded RFID tags facilitate maintenance operations by providing access to information and repairing background.

Thus, Primo1D’s new RFID solution promises to be more durable and more adapted to this use case on the retail market.