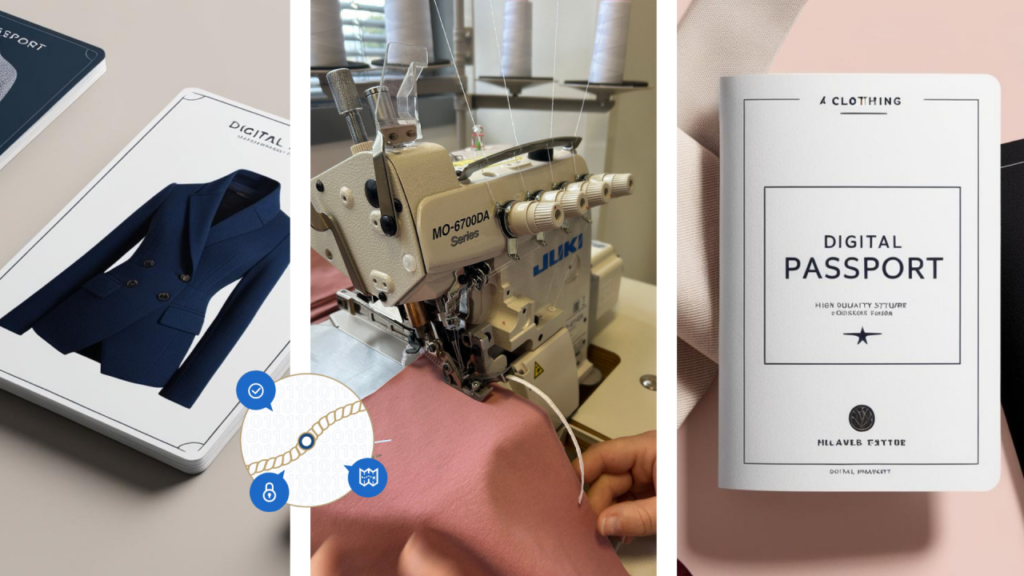

The fashion and textile industry is undergoing a massive transformation. Sustainability regulations, such as the upcoming Digital Product Passport (DPP), are pushing brands to provide detailed product information throughout the entire lifecycle—from manufacturing to recycling. At the same time, consumers are demanding transparency. They want to know where their clothes come from, what they are made of, and how to care for them sustainably. To meet these needs, manufacturers must evolve—offering not only high-quality garments but also a digital infrastructure that enables full traceability, circular economy integration, and a better customer experience.

This is where E-Thread™ embedded RAIN RFID technology comes in.

The solution: RFID-embedded textiles as a key to a complete data platform

Primo1D’s E-Thread™ technology allows manufacturers to integrate RFID tags directly into the garment during production. Unlike traditional labels or external RFID tags, E-Thread™ is embedded under overlock stitching, making it invisible, tamper-proof, and seamlessly integrated into the product. The tag cannot be removed or counterfeited, ensuring reliable tracking from the moment the garment is produced until it reaches the recycling stage. This innovative solution withstands up to 100 washing cycles, making it ideal for second-hand markets, rental services, and circular economy initiatives.

More than just an identifier, E-Thread™ creates a unique digital identity for each product, enabling brands and consumers to access essential data at any point in the lifecycle by linking it to their database. Manufacturers who integrate this technology provide their brand partners with a powerful, cloud-connected product database, storing critical information such as material composition, production history, sustainability impact, and care instructions. The ability to track garments throughout their entire lifecycle allows brands to optimize supply chains, enhance transparency, and meet growing regulatory requirements.

How RFID traceability contributes to the Digital Product Passport (DPP)

The introduction of the Digital Product Passport (DPP) is set to revolutionize the textile industry, requiring brands to disclose detailed traceability and sustainability information. By embedding E-Thread™ RFID tags into garments, manufacturers can help brands comply with these regulations effortlessly. Since RFID tags store and update product data in real-time, brands can ensure automatic compliance with the DPP, without the need for additional tracking systems.

This level of traceability is not only beneficial for compliance but also enhances consumer engagement. The resale and recycling industries also gain from this transparency, as E-Thread™ simplifies the large-scale sorting and processing of garments at the end of their lifecycle—a key challenge for industrial recycling. By seamlessly integrating traceability into fashion, manufacturers play a pivotal role in building a more sustainable and responsible industry.

Manufacturers: it’s time to future-proof your business

The shift toward traceability, sustainability, and circularity is no longer optional. Textile manufacturers who integrate RFID technology today will not only future-proof their operations but also become essential partners for brands navigating this evolving landscape. By embedding E-Thread™ RFID tags, manufacturers can provide value-added data services to their clients, streamline compliance with sustainability regulations, and enable brands to build stronger, data-driven relationships with consumers.

Beyond regulatory compliance and consumer engagement, integrating E-Thread™ RFID also optimizes inventory and supply chain management. Enhanced visibility into stock levels and product flows leads to better forecasting, reduced waste, and improved operational efficiency. This increased agility directly contributes to a stronger return on investment (ROI), making digital transformation not just a necessity, but a strategic advantage.

With increasing pressure from consumers, regulators, and environmental advocates, the textile industry must embrace transparency and digital innovation. By integrating E-Thread™ RFID, manufacturers position themselves at the forefront of this transformation, creating garments that are not only smarter but also sustainable, trackable, and future-ready.

Are you ready to revolutionize textile traceability? Contact Primo1D to learn how E-Thread™ can transform your manufacturing process and empower your brand partners.